In comparison to other thermal spray methods, plasma spraying ist the most universal development. The plasma-methods can be grouped into four areas: atmospheric, under vacuum, under water and under gas pressure.

This variety and the very high energy-offer of Plasmaspraying allows to process each and every material that is available in powder-form and that has a melting-point/melting-range.

Because of it's technical characteristics, the the Plasmaspray is the ideal technology for coating applications in vessles/boilers. Other than conventional or HVOF flamespray, the Plasmaspray does not use flamable gas and no additional heat is transfered to the substrate beside the one that the molten particle brings to the substrate's surface.

As there is no punctual heat introduction, there is no risk of bringing tension into the base-material or even dimensional distortion of tubes.

The spray-gun converts the immense thermal energy and the high speed of the Plasma-beam to molten powder particles with very high kinetic energy. With these particles, the tubes or other parts and work-pieces are coated with high precision.

The mobile equipment to coat high-duty parts and elements by Plasmaspray is mainly used for on-site coating at customer's place and is a patented invention of our Mr. Bodo Häuser. Up to 60m in hight we can reach and coat bigger or smaller areas at customer's installations from of scaffolding or existing inspection facilities like lift-cages.

Of course we can coat on-site as well at customer's installations and as well complex surface-geometries, or "over-head" areas like boiler-roof, by using our Plasmaspray-technology.

We can apply as well coatings with properties like insulating, thermal-shock-resistant or coatings apt to resist alterating thermal stress. Depending on customers demand, we can as well apply coating-layers that are resistant to flue-gas-corrosion, abrasion/erosion, electrically isolating or conductive.

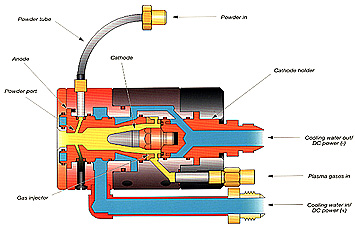

In the front casing part of the plasma gun, an electrical arc is stabilised by the supply of gas and is ignited between a finger-shaped tungsten cathode and an nozzle-shaped copper anode surrounding it. The gas which is fed in via an injector and heated up in the process is argon to which helium, hydrogen or nitrogen can be added when special materials are to be processed. If argon is used as a plasma gas, the heating of the gas brings about ionisation processes producing an electrically conductive gas known as plasma. The ionisation process brings about an increase in the volume of the gas of around x100 and due to the geometry of the nozzle-shaped copper anode, the plasma jet reaches velocities of up to mach 2. The temperature of the plasma jet, if argon is used, is about 18.000°C.

To ensure that the plasma gun is not destroyed at this high temperature, intensive cooling with ca. 25 litres of water per minute at a pressure of 18 bar is necessary. The water is supplied via the front casing part and fed back to the heat exchanger via the cathode holder located in the central casing part.

The powdered material to be applied is fed via an argon gas flow into the plasma, which is leaving the gun axially as a jet, gets melted and is accelerated to reach the surface to be coated. The plasma recombines directly after leaving the gun and passes into the surrounding atmosphere as normal gaseous argon.

This essential point distinguishes the plasma spraying from all of the other thermal spraying processes: The plasma-beam does not reach the surface to be coated! This important characteristic means that the surfaces to be coated does not get any hotter than ca. 70°C. So it is also suitable for coating tubewalls with a remaining wall-thickness of around 2.0 mm. In several waste-incineration boilers with very little remaining wall thicknesses, our coating allowed a larger number of years of additional lifetime.

Plasma spraying can be applied whre others methods fail and can offer good and practical solutioas to the maintainance-concepts of our customers.