Particularly the Plasma- and Laserspray Technology are appropriate methods to apply coatings to repair or restore machine building parts, armatures, fittings, valves, bearings, rolls or drive-shafts.

Depending on the application, different coating materials are used.

- For armature, valves, etc., often "Stellite 21" and "SKWAM" are used.

- For machine building parts as well Ni-base-alloys ("Monel", "Hastelloy", "Inconel") or (oxid-)ceramics, like Al-oxides, Zirconium-oxides etc.

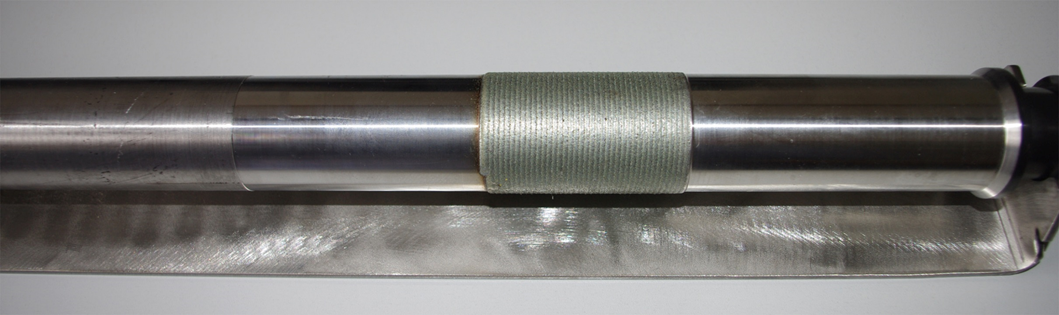

The picture illustrates the different work-steps to restore the worn-out surface of a armature-spindle:

Four segments (from left to right) show:

1st from left: worn-out surface of a valve-spindle with safety function. Due to the numerous scratches and corrugations, it can not be used anymore. In the past, it had to be replaced by a new one.

2nd from left: the spindle is machined to peel-off damaged surface until scratches and corrugations are removed. The resulting undersize may reach even some millimeters diameter.

3rd from left: The cobalt-base-alloy "Stellite 21" with metallurgical bond to the spindle surface has been applied by using Laserspray-Technology. The coating-layer may reach even some millimeters of thickness.

4th from left: Lasersprayed coating after dressing to size by mechanical treatment in turning machine and grinding.

Realizing roughness of Rz 3-4 and, with the effect of the cold-work-hardening, a surface-hardness of up to 50HRc can be accomplished! This lowers the risc of damage by mechanical stress considerably.

Because of it's very good corrosion-protection properties, "Stellite 21" represents in many cases a very good – sometimes even better – alternative to the base material used before.

In our case, we were able to avoid the need of a cost- and time-intensive replacement. The valve-spindle was succesfully repaired and once again „ready to use“ !